Impact printing is based on the transfer of ink from a ribbon onto paper, as caused by the hit of a striking mass (hammer, needle…) on a stamping form.

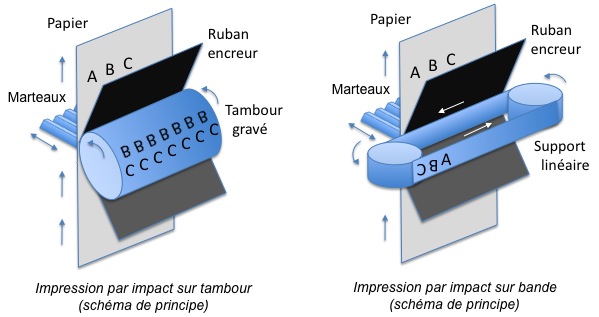

Usually, the stamping form consists of relief images of the alpha-numeric characters to be used. These images are arranged on a character carrier in such a way they can be sequentially addressed. The carrier can take one of different forms: drum cylinder, bar, chain or belt. In high speed impact printers, hammers are selectively fired and hit the moving characters on-the-fly. Such methods are nevertheless limited: printing speed limits due to inertial consideration (moving parts), practical size of character sets, no graphical capability.

In impact matrix printers, the shape of each character is obtained by a combination of the dots created by the impacts of needles. Larger character sets can be used, and some graphical capability does exist, but printing speed remains dramatically low.

Bull at Belfort had developed several models of solid font impact printers, based on hammer and drum technology, before it created in 1970 a proprietary linear character carrier technology in the form of an endless flexible metal belt. The main innovation was the positioning of the character images on the tip of flexible fingers, allowing for higher belt speed with no compromise on print quality.