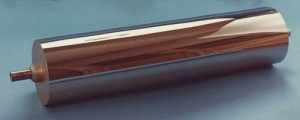

Magnetographic drum… its structure

The original drum was a 4-inch diameter, hollow cylinder, made up by the assembly of Fe-Si circular slices (to reduce eddy currents). Such drum core sheeted structure was soon replaced by a simpler and more efficient aluminum tube. On the drum core surface, a layer of Fe-Ni (high permeability material, aimed at providing an easy return path to the write recording fields) is first grown by electroplating. A second layer, made of Co-Ni-P (high coercivity magnetic material, aimed at keeping memory of the written dots), is then electroplated on top of the first. Finally, a sub-micron thick, sputtered layer provides mechanical protection against wear. Drum lives of 20 to 30 millions pages were achieved.

A larger, 6-inch diameter, drum was later introduced in third generation printer products. In the meantime, internal water cooling of drums allowed for higher and higher printing speeds.

A larger, 6-inch diameter, drum was later introduced in third generation printer products. In the meantime, internal water cooling of drums allowed for higher and higher printing speeds.